Fighting Against Water

Hello everyone, this post is regarding an issue we have been working through over the last few months, particularly in relation to our role in the MINKE project. As part of the project, we developed the Smart Citizen Water Station which integrates sensors from Atlas Scientific.

Today, we’ll be addressing the topic of cable waterproofing, so that the kit can be deployed correctly for the use case of the project (with the connectors under the surface of the water).

We went through a number of iterations on how to best ensure the waterproofing. These iterations, and the issues that we had with each one will be outlined in detail below. But here is a quick chronological list of our attempts:

- Coax-Seal (as recommended by Atlas Scientific)

- Electrical tape and Coax-Seal (as recommended on a waterproofing forum)

- Resin (as recommended by a project partner)

- Re-enterable gel

Additional Technical Information

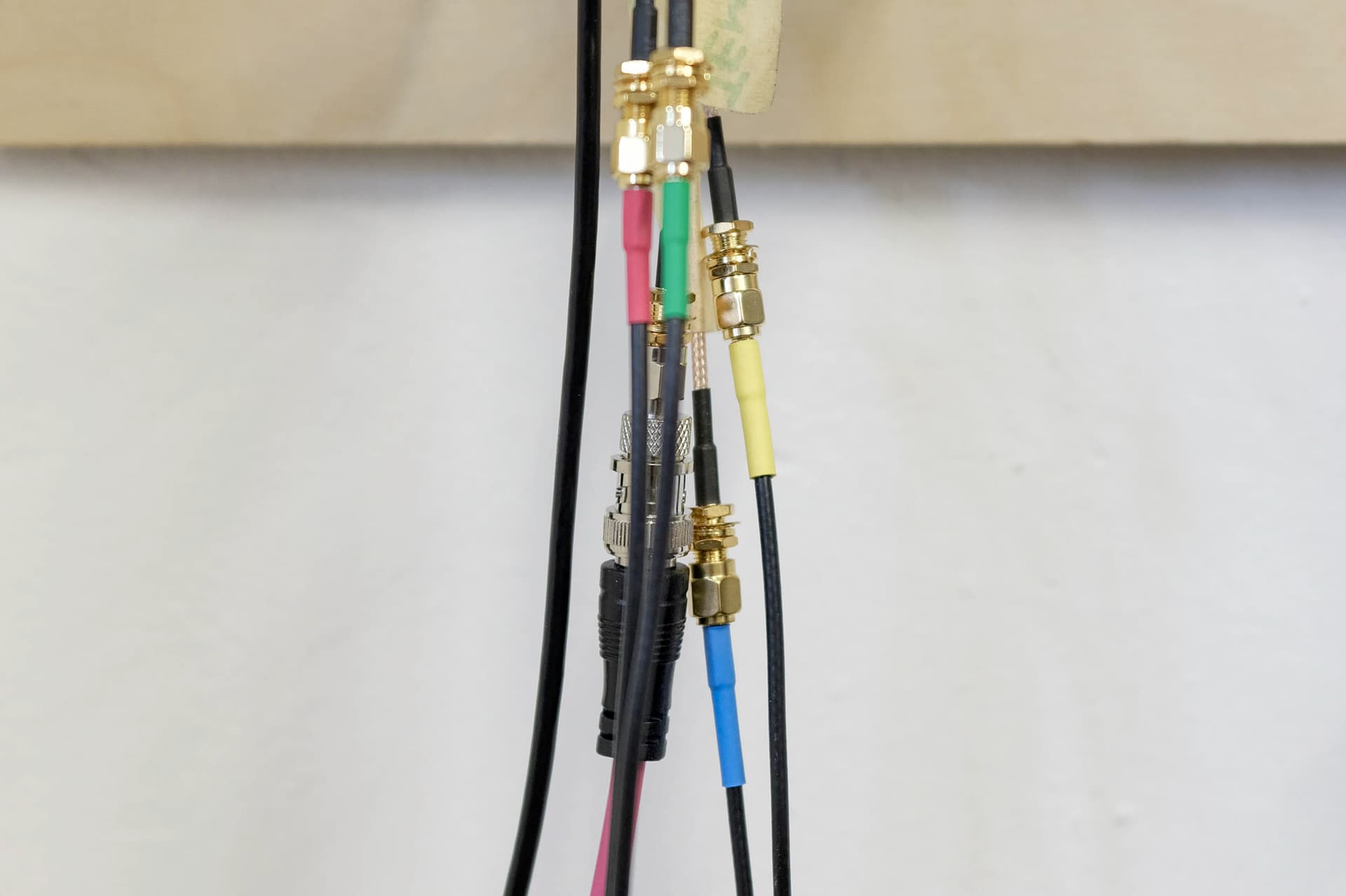

The Smart Citizen Water Station makes use of 5 Atlas Scientific probes which measure: pH, temperature, oxidation-reduction potential, dissolved oxygen, and conductivity. Each of the probes has approximately 50cm of fixed cable, so it is necessary to use extensions.

This point of extension is, by necessity, beneath the water in most use cases for the Smart Citizen Water Station, so we knew that we needed to find a way to properly seal the connectors to ensure the proper functionality of the kit, and avoid any damage to the probes.

More on the Cabling Extension

Image credit: Atlas Scientific

The probe cabling extension system consists of a Multicomp Pro RG179 75 Ohm SMA male to SMA female coaxial extension cable, with a maximum length of 50m. This length is adaptable with the use of additional cables (typical lengths are 3m, 7.5m or 30m), although the impedance of the wiring must be maintained at the 75 Ohm value. This means that the additional cables must be used at their designated lengths; any attempt to shorten them manually will affect the Ohm value and result in incorrect readings. The cable’s insulating coating is Teflon, with Titanium Nitride connectors, and PVC joints.

Our Use Case and Specific Needs

While many of the waterproofing solutions described below can be an adequate or superior solution depending on the circumstances, our use case was very particular.

We needed to find a solution that is:

- Waterproof (not just water resistant)

- Submergible (in both salt and fresh water)

- Non-toxic and insoluble (we want to measure the water, not contaminate it)

- Inert (we do not want to influence the measurements of our devices)

- Re-enterable (for repairs and maintenance)

Waterproofing Iterations

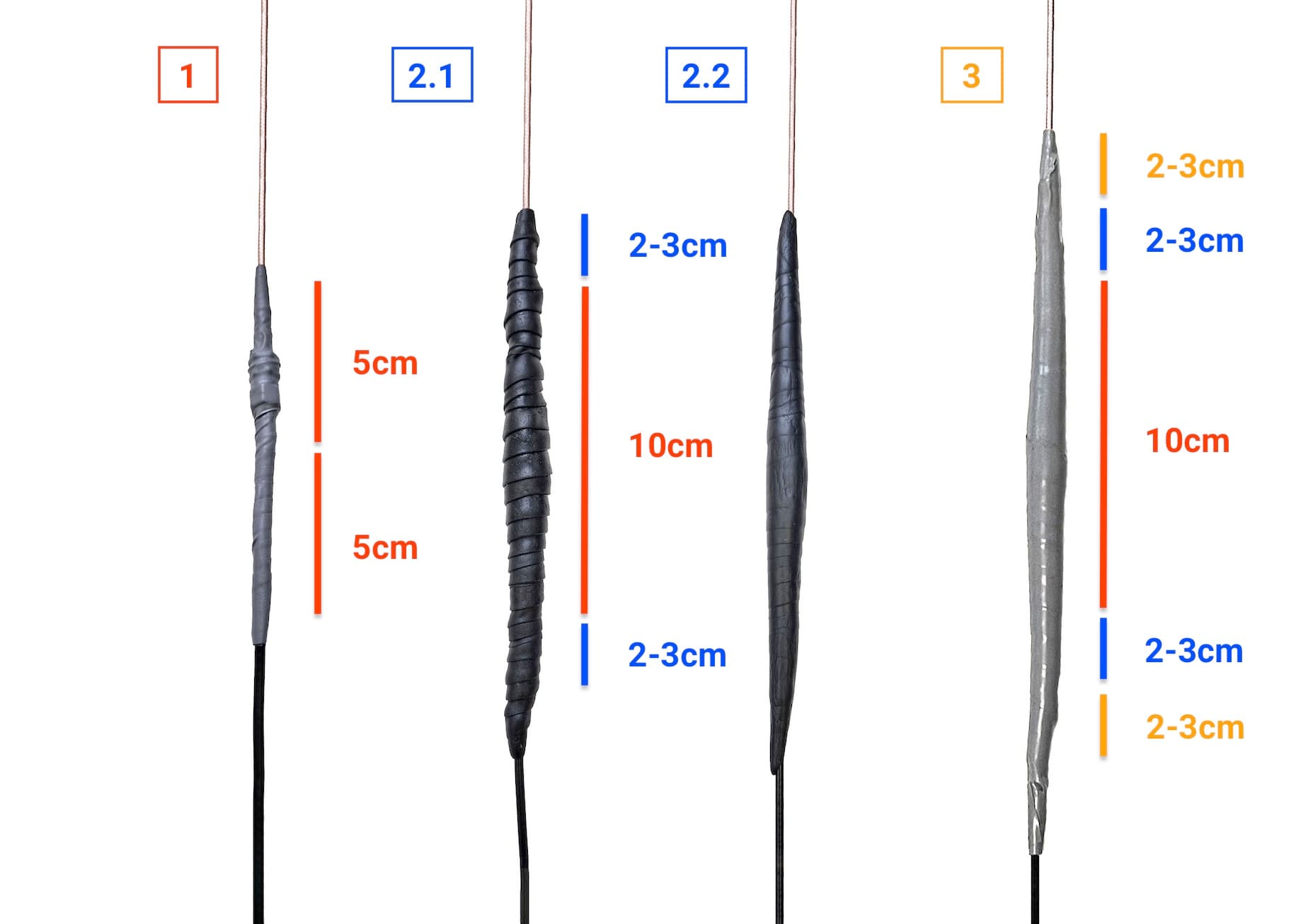

We went through four iterations in our waterproofing tests. They are presented here in order, but for those who want details on the best option for our use case, click here to jump to the section on Re-enterable Gel.

Coax-Seal

Coax-Seal is a “hand moldable plastic” which is marketed for sealing connectors from moisture and corrosion. The solution is recommended by AlphaSense and sold alongside their probes on their website. It seems like it would be a good solution for weatherproofing, and that it might be an one-stop product for rainproofing outdoor cabling, but we didn’t test for those conditions specifically. We needed underwater (sometimes deep water) submersion of the probes and their connectors.

Image credit: Atlas Scientific

ISSUES:

- Repeated failures in deployment (especially when used in isolation)

- The larger connector for the temperature probe had a very low success rate (probably because of the differences in diameter between the cabling and the connector).

- We began using a different connector for the temperature probes in later iterations, but we did see failure in the deployment of all sensor types with the Coax-Seal solution.

Electrical tape and Coax-Seal

Once we realized that Coax-Seal alone would not be an adequate solution, we took to the internet scouring forums on waterproofing cables. We found a post, purportedly by an ex-marine explaining how the cables were waterproofed on marine ships.

Bingo! Or so we thought…

We tried testing a number of cables with this method, and they seemed to be holding up. We were so confident with the solution that we created a guide on how to apply the layers of tape.

Over the long term, we started to see higher failure rates than we found acceptable. Our opinion is that this solution is more appropriate for weatherproofing outdoor cabling (above ground), but we didn’t test for those conditions specifically.

ISSUES:

- Long-term failures in deployment

- The failure rate was lower than the Coax-Seal solution, but over the long-term it was still unacceptably high

- Especially in deep water deployment, the solution did not hold up

- Elaborate process that was very time consuming

- Difficulty in removing the tape when we needed to troubleshoot or replace sensors

Resin

Once we started seeing a breakdown in the tape layering system over longer term use, we turned to some of our project partners for solutions. One of the partners we work with suggested that a resin could be a good solution for water tight sealing from water.

We ordered a number of cable sealing kits, but decided that the solution was too risky. It did not offer any possibility for re-entry once the resin was used. We believe this could be a good solution in instances where there is no chance that re-entry will be necessary, but we knew from experience that our use case was more complicated. If we sealed 5 sensor connectors in resin, and just one connector failed, we wouldn’t be able to go back in and make repairs.

ISSUES:

- Resin materials can be harmful and even toxic during deployment

- We didn’t find clear information on whether all the materials used were non-toxic and inert once they were fully hardened

- Resins are by nature permanent, leaving no room for error or re-entry

Re-enterable Gel

Finally, we found the Ray Tech re-enterable gels. After consulting with the company, we determined that their Magic Power Gel was the most adequate, particularly because it works well for complete waterproofing in salt water and fresh water. Likewise, it is effective in deep water deployment.

Image credit: Ray Tech

The company website is clear that the gel is non-toxic, insoluble and inert.

The gel is not only re-enterable, but it is also re-usable upon re-entry, meaning that you can go back in, remove the gel, and reapply the same gel without having to throw it away (as long as the size hasn’t been greatly affected).

ISSUES:

- The substance can be very sticky

- The gel does not come with a deployment enclosure (we used torpedoes that came with the resin kits we bought and decided not to test)

- We are working on a design of a 3D printed version which will hopefully be on our Enclosure Respository soon.