Hi all!

We have been having some fun at the lab and running tests aiming to destroy 4 devices with water  .

.

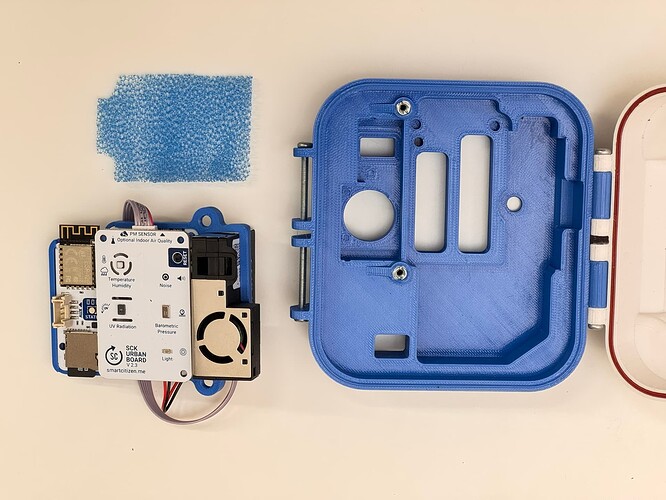

We tested a total amount of 4 kits: 2 with additional protection besides the enclosure, and two control SCKs in an enclosure, but without any additional protection. The protection we applied was as follows:

- Nail barnish applied manually to each sensor pins.

- Foam covering the sensors

The test sequence aimed to simulate two extreme rain conditions  : vertical and lateral (almost horizontal). Finally, to those kits that survived, we directly watered the kit with the hose.

: vertical and lateral (almost horizontal). Finally, to those kits that survived, we directly watered the kit with the hose.

Water testing the SCK video

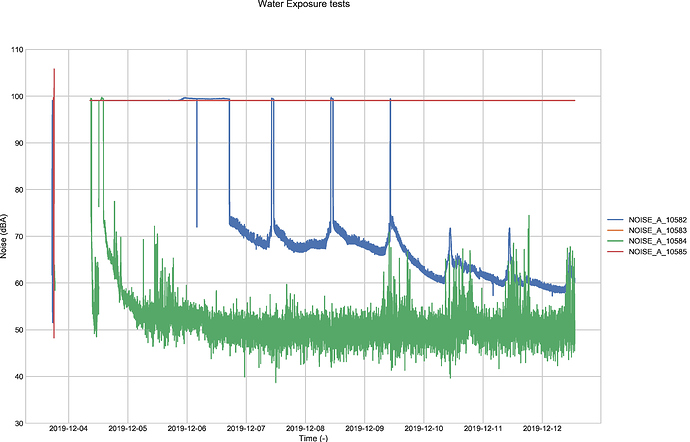

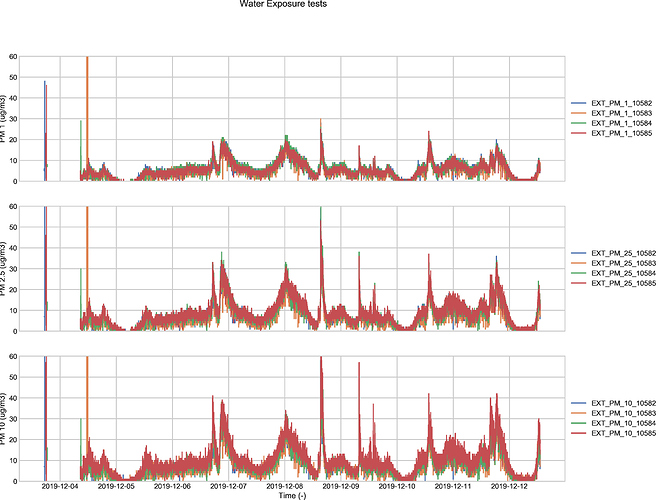

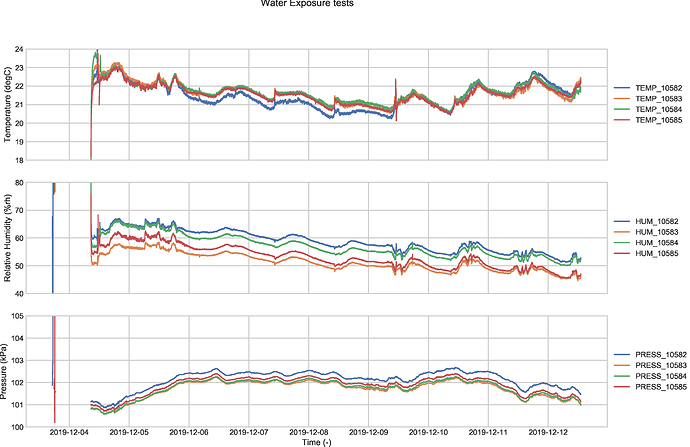

The devices failed at different stages of the test sequence. The less protected kits showed a failure on the microphone with a constant value of 99dBA. The rest of the sensors were still functioning properly, and the humidity was 100%rh in most of the cases except the device protected with foam.

The Urban Board failed once water reached the PCB and could go into the sensors themselves. The failure seems to be a short that produces a blue powder from the copper reacting with the water, visible at plain sight in the SHT31, the CCS811, …

The nail polish prevents this from happening, although it can’t help with the microphone issue. If water is deposited on top of the microphone, it will very likely be at 99dBA.

The foam covering the sensors seems to prevent water deposition on the microphone and, in general, on the PCB. This solution, combined with the nail polish would be the best option for protecting the kit.

Summary of guidelines:

- The device is not to be placed outdoor without an enclosure. We recommend a design which exposes the sensors facing down.

- If you need to place the sensor outdoors, an enclosure is necessary

-

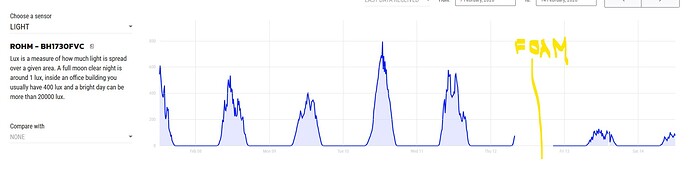

Water deposition on the microphone provokes the readings to be at 99dBA. This is the only failure mechanism so far, but there might be others, such as dust. For this reason, a coarse foam can help such as the one below. Keep in mind that this will affect the light sensor readings.

- We can recommed something like this (PPI-20/10) for the foam: http://www.infiltro.es/index.php/filtro-de-aire-2/prefiltros/item/foam

- Water infiltration into the sensors area can provoke sensor failure and the Urban Sensor Board to not function. Nail polish can help to prevent this.

What to do if this happens?

After destroying the kits, we placed them back indoor overnight and checked them again. All the devices, except the one with nail polish showed the blue copper byproducts, but all of them seemed to have normal SCK base board functioning (charge, LED, button response…) and all of them detected the urban sensor board. Only one of the sensors read abnormal values in the PM sensor and all of the devices shows a noise value of 99dBA, although we have seen the microphone drying out and come back to life after some time in indoor conditions.

Other sensors affectation

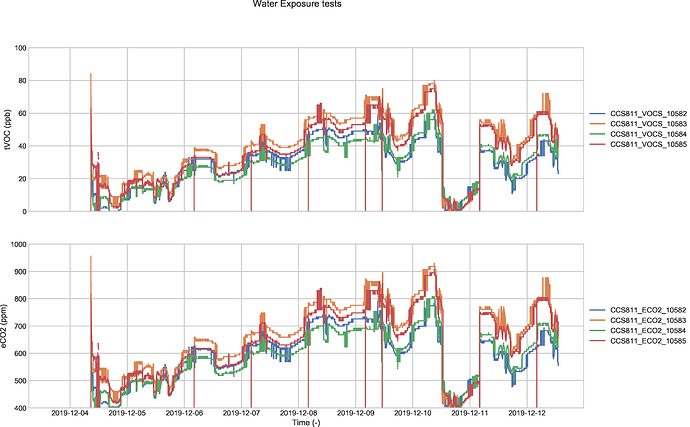

As you can see from the graphs, not only humidity readings are affected by the water, but also the microphone and the eCO2, tVOC sensor. The CCS811 is directly affected by the highly humid conditions not only because the sensor is exposed to water, but also because the calculation of the metrics use the humidity from the SHT31 T/H sensor. This causes the internal algorithm of the CCS811 to yield some weird values, and they should not be trusted when this happens. In the graphs, you will also see that the sensor gives some very high or low values, and that it stays flat for 1min each time, because of it’s mode of operation.

Extra ball: Why blue copper?

From http://www.circuitnet.com/experts/86722.html:

Blue copper compounds can include copper hydroxide (Cu(OH)2)- light blue, which can convert to copper carbonate (greenish); copper nitrate (Cu(NO3)2) and copper sulfate (CuSO4). Greencopper compounds include copper chloride (CuCl2) when oxidized and coppercarbonate (CuCO3). These copper cmpds indicate inadequate cleaning.

That’s it for now!