3D-Printed Waterproof Case for SCK 2.3

Hello everyone!

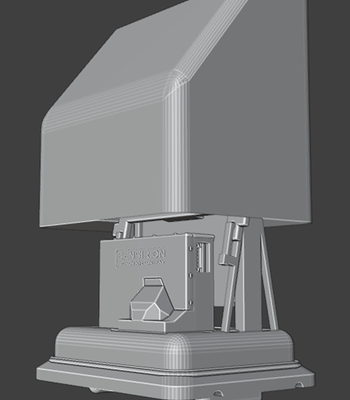

We have been exploring ways to develop a waterproof case using only 3D printing.

The idea is that anyone can easily access an enclosure design using the most common tool in our workshops — a 3D printer.

This enclosure was developed during the CitiObs EU project and deployed in Oslo.

Design Concept

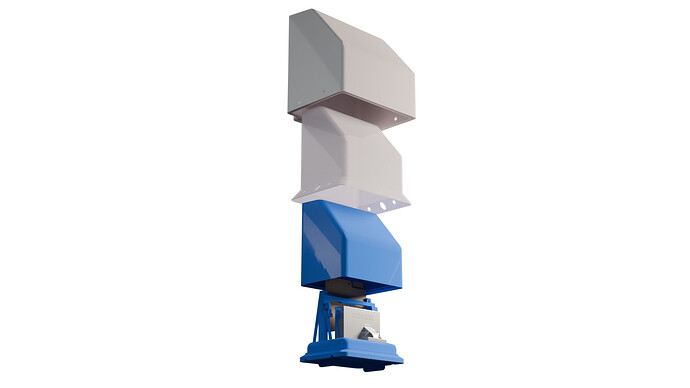

The enclosure consists of several layers of 3D-printed pieces, with different materials in between.

The goal is to make it as difficult as possible for water to seep through the printed layers.

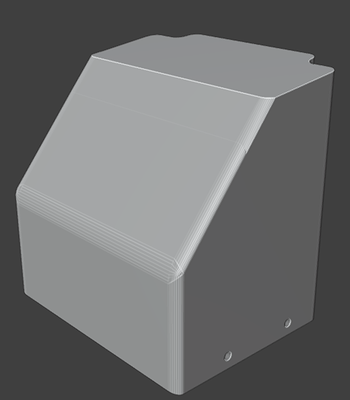

Outer Layer

The outer layer is the thickest one and is directly exposed to the environment — rain, wind, snow, and sun.

We chose PETG for its reliability in outdoor conditions and for its flexibility, which should help it withstand temperature changes between winter and summer.

This part is printed in white to avoid overheating.

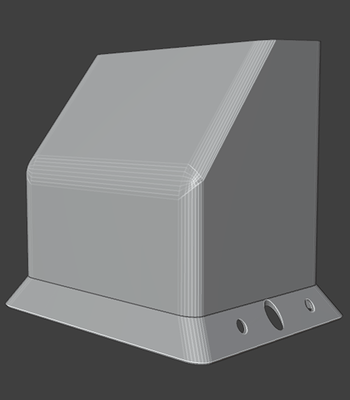

Second Layer

The second layer is also printed in PETG, but it is much thinner and in a translucent color so we can see the gap between the first and second layers.

Before assembling them, we covered the outer side of the second layer with a thin plastic bag secured with a rubber band. This way, we gave an extra level of waterproofing to ensure the electronics are protected.

Foam Insulation

The gap between the two PETG layers is filled with polyurethane foam, which serves three purposes:

- Waterproofing the entire structure

- Thermal insulation for the inside of the box

- Bonding the two printed parts together

This “shell” should give us good protection from the rain!

In future iterations, we hope to try cleaner options maybe with recycled material, but this time we wanted to ensure that the electronics were well protected.

Inner Layer & Electronics

The inner layer is printed in PLA to make it easier to produce.

It includes a base where all the electronics are mounted.

In this case, we only needed to measure a few parameters, so the Sensirion SEN5X sensor was used.

This version provides PM measurements and includes an internal temperature and humidity sensor, with VOC and NOx indexes.

Field Test in Oslo

This enclosure has been in use in Oslo since the end of January 2025 as part of a pilot deployment.

A total of 20 Smart Citizen Kits equipped with the 3D-printed waterproof enclosure were installed in various outdoor locations across the city.

The goal of the deployment is to evaluate the enclosure’s long-term performance in Nordic weather conditions while collecting environmental data such as PM (particulate matter), temperature, and humidity.

These units are actively transmitting data to the Smart Citizen Platform, where they can be monitored in real time.

You can follow the live readings and see the project details here: 3D Printed Enclosure for Outdoor.

Field test in Barcelona

Barcelona is also a good place to test these devices, especially in summer, with hot conditions mixed with torrential downpour. We have installed a device with a solar panel (subject for another topic soon!)

You can see the link to the device here: https://smartcitizen.me/kits/18206.

. The first piece was a bit explosive… Apply the foam into the transparent part; once everything is filled, assemble it quickly so that, after curing, everything fits in the correct position. (pictures 3–5)

. The first piece was a bit explosive… Apply the foam into the transparent part; once everything is filled, assemble it quickly so that, after curing, everything fits in the correct position. (pictures 3–5)